Table of Contents

What is Quality Control?

Quality control is the process of ensuring products and services meet specific standards. It encompasses everything from inspecting raw materials to testing finished goods, aiming to identify and eliminate defects. It may be defined as a system that is used to maintain a desired level of quality in a product or service. It is the systematic control of various factors that affect the quality of the product. It depends on the materials, tools machines , types of labor, working conditions etc. Quality Control aims at prevention of defects at the source, relies on effective feedback system and corrective action procedure.

According to Juran “Quality Control is the regulatory process through which we measure actual quality performance, compare it with standard and act on difference”.

Why is quality control important?

QC isn’t just about preventing faulty products. Here’s how it benefits everyone:

- Consumer Safety: QC safeguards consumers from products that could cause harm or malfunction.

- Brand Reputation: Consistent quality builds trust and keeps customers loyal.

- Cost Savings: Identifying problems early avoids costly rework and recalls.

- Process Improvement: QC data helps identify areas for improvement in production.

Types of Quality Control

Quality control (QC) isn’t a one-size-fits-all approach. Different methods are employed at various stages of production or service delivery. Here, we delve into the Three Core Types of Quality Control:

- Inspection: This is the direct examination of products or services to ensure they meet predetermined specifications. Inspections can be visual, involving human inspectors checking for defects, or they can utilize specialized equipment for automated testing. There are different types of inspections depending on the stage of production:

- Source Inspection: Performed at the supplier’s facility to ensure raw materials or components meet quality standards before they even enter the production process.

- In-Process Inspection: Conducted throughout the production line at various stages to identify and rectify defects early on.

- Final Inspection: The last hurdle before products are shipped, ensuring they are free from flaws and meet all quality criteria.

- Testing: This method goes beyond visual examination and involves simulating real-world conditions or running specific tests to assess product functionality, performance, and durability. Testing can be destructive (where the product is intentionally damaged to assess its breaking point) or non-destructive (using specialized equipment to evaluate performance without harming the product).

- Statistical Process Control (SPC): This proactive approach utilizes statistical techniques to monitor and analyze production data. By charting data points and control limits, SPC helps identify trends and variations in processes. This allows for early intervention and corrective action before defects occur, ensuring consistent quality throughout production.

These three core types of QC work together to create a robust quality management system. Inspections catch flaws, testing assesses performance, and SPC proactively identifies potential problems. By implementing these methods effectively, businesses can achieve:

- Reduced production costs: Early detection and rectification of defects minimizes waste and rework.

- Improved product quality: Consistent monitoring ensures products meet quality standards.

- Enhanced customer satisfaction: Delivering high-quality products fosters trust and loyalty.

- Streamlined processes: Identifying process variations allows for optimization and efficiency gains.

By understanding and utilizing these three pillars of quality control, businesses can build a strong foundation for achieving operational excellence and delivering superior products and services.

The Future of Quality Control

Technology is transforming QC. Here are some exciting trends:

- Automation: Robots and AI are performing inspections with increased speed and accuracy.

- Big Data Analytics: Analyzing vast datasets helps predict and prevent quality issues.

- Cloud-Based QC Systems: Sharing data across the supply chain for real-time quality monitoring.

Objectives of Quality Control

Quality control (QC) has several key objectives that ensure a smooth-running operation and consistent quality in the final product or service. Here are the main ones:

- Ensure Conformance to Standards: The primary objective is to verify that products or services meet predetermined specifications and industry regulations. This involves inspections, testing, and data analysis to identify any deviations from set standards.

- Enhance Product Quality and Reduce Risks: A robust QC program aims to minimize defects and errors throughout the process. This not only improves the overall quality of the final product but also reduces the risk of product failures, recalls, and potential safety hazards.

- Gain Production Efficiencies: Effective QC practices can identify bottlenecks and inefficiencies in production. By addressing these issues, companies can streamline processes, reduce waste, and ultimately save on production costs.

- Garner Customer Loyalty: Consistent delivery of high-quality products fosters customer trust and satisfaction. Customers are more likely to become loyal brand advocates when they can rely on a company’s commitment to quality.

- Continuous Improvement: Quality control is not a one-time activity. It’s an ongoing process that seeks to continuously improve quality management system. By analyzing QC data, companies can identify areas for improvement and implement changes to further enhance overall quality.

In essence, quality control works to prevent problems before they occur, ensuring a smooth-running operation, a strong brand reputation, and satisfied customers.

Benefits of QC

Quality control (QC) isn’t just about nitpicking imperfections; it’s the guardian of excellence in the world of products and services. By implementing a strong QC system, businesses reap a multitude of benefits that impact not only their bottom line but also customer satisfaction and industry standing. Let’s delve into the key advantages of quality control:

- Enhanced Customer Satisfaction: QC ensures that products and services meet or exceed customer expectations. Consistent quality builds trust and fosters brand loyalty, leading to repeat business and positive word-of-mouth promotion.

- Reduced Costs: Proactive identification of defects through QC minimizes the need for costly rework and recalls. Additionally, by streamlining processes and reducing waste, QC contributes to overall production efficiency and cost savings.

- Improved Brand Reputation: A commitment to quality control builds a strong brand reputation for reliability and excellence. This not only attracts new customers but also positions the company as a leader in its industry.

- Increased Safety: QC plays a crucial role in ensuring the safety of products, especially those critical to health and well-being. By catching flaws early on, QC safeguards consumers from potential hazards.

- Streamlined Processes: QC data analysis helps pinpoint areas for improvement in production processes. Addressing these inefficiencies leads to smoother operations, faster production times, and ultimately, increased productivity.

- Competitive Advantage: In today’s competitive landscape, consistent quality is a key differentiator. By prioritizing QC, businesses can set themselves apart from competitors and gain a significant edge in the market.

- Regulatory Compliance: Many industries have specific quality standards and regulations. Effective QC ensures that products and services adhere to these requirements, avoiding legal issues and potential fines.

- Data-Driven Decision Making: QC data provides valuable insights into production processes and customer feedback. This data can be used to make informed decisions about product development, resource allocation, and overall business strategy.

- Continuous Improvement: QC is an ongoing process that fosters a culture of continuous improvement within a company. By constantly evaluating and refining QC procedures, businesses can strive for ever-increasing levels of quality.

- Reduced Risk: A robust QC system minimizes the risk of product failures, malfunctions, and safety hazards. This not only protects consumers but also mitigates potential liabilities for the company.

In conclusion, quality control offers a multitude of benefits that extend far beyond simply catching defects. It’s a strategic investment that ensures customer satisfaction, cost savings, a strong brand reputation, and a competitive edge – all vital ingredients for long-term business success.

Seven tools of QC

Ensuring consistent quality is no small feat. But fear not, quality control professionals have a trusty arsenal at their disposal: the Seven Basic Tools of Quality Control. These simple yet powerful tools facilitate data collection, analysis, and problem-solving, empowering businesses to achieve excellence. Let’s explore these champions of quality, one by one:

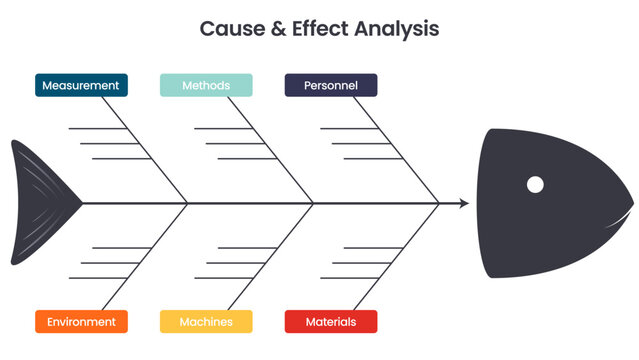

Cause-and-Effect Diagram (Fishbone Diagram):

Example: Fishbone

Also known as the Ishikawa diagram, this tool visually identifies the potential causes of a quality issue. It resembles a fishbone, with the main problem at the head and branches representing various contributing factors like manpower, materials, methods, and machines.

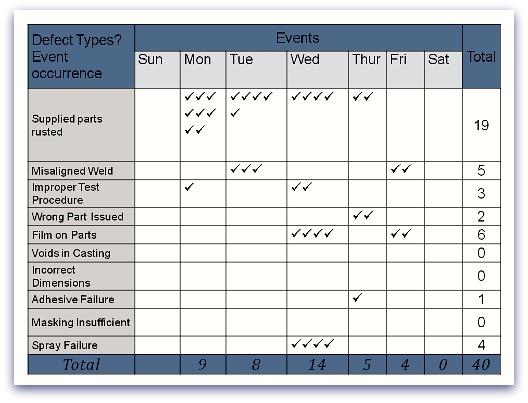

Check Sheet:

Example: Check Sheet

This is a simple data collection tool, often a pre-formatted form, used to record the frequency and type of defects or observations. Check sheets provide a structured way to gather consistent data over time.

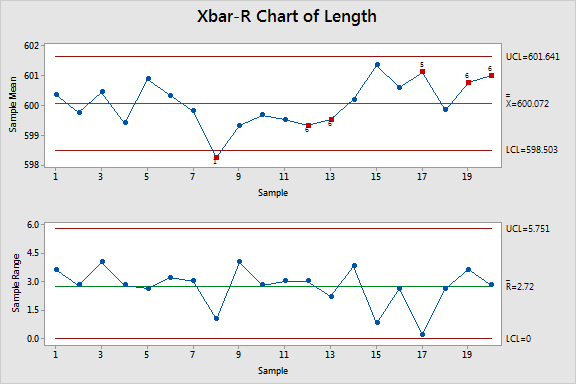

Control Chart:

Example: Control Chart

This graphical tool helps monitor a process over time and identify any deviations from set standards. By plotting data points and control limits, control charts reveal trends and signal potential issues requiring corrective action.

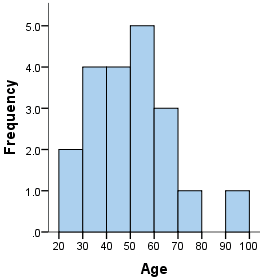

Histogram:

Example: Histogram

This bar chart depicts the distribution of data, providing valuable insights into the frequency of specific values. Histograms help visualize how data clusters and identify potential nonconformities in a process.

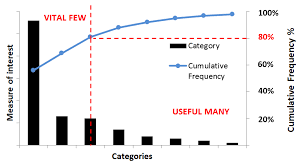

Pareto Chart (80/20 Rule):

Example: Pareto Chart

This chart highlights the most significant factors contributing to a problem. It follows the Pareto principle, where roughly 80% of the effects come from 20% of the causes. This prioritizes efforts by focusing on the most impactful areas for improvement.

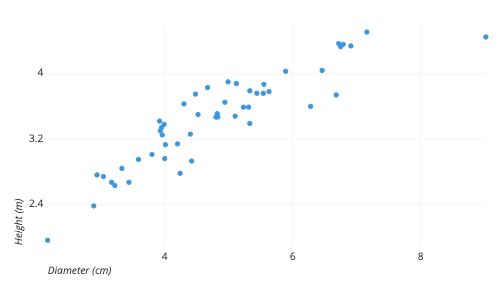

Scatter Diagram:

Example: scatter diagram

This tool investigates the relationship between two variables. By plotting data points on a graph, scatter diagrams can reveal potential correlations or cause-and-effect relationships between factors influencing quality.

The example scatter plot above shows the diameters and heights for a sample of fictional trees. Each dot represents a single tree; each point’s horizontal position indicates that tree’s diameter (in centimeters) and the vertical position indicates that tree’s height (in meters). From the plot, we can see a generally tight positive correlation between a tree’s diameter and its height. We can also observe an outlier point, a tree that has a much larger diameter than the others. This tree appears fairly short for its girth, which might warrant further investigation.

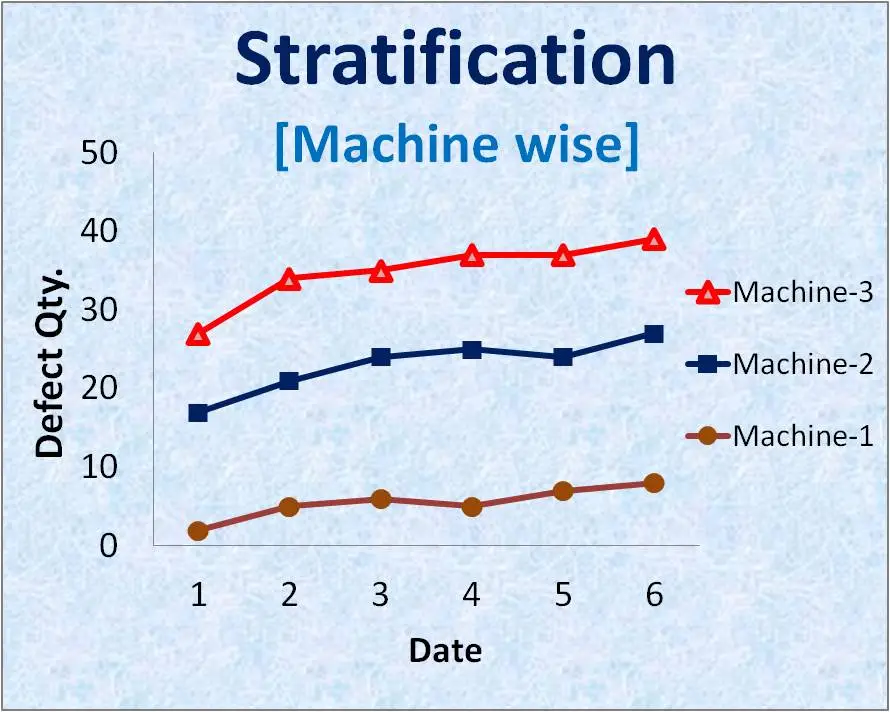

Stratification:

Example: machine wise scarification

This technique involves dividing data into subgroups based on specific characteristics. By analyzing data from these subgroups, it helps identify patterns or trends that might be masked when examining all data points together.

Rejection data collected from three different machines and date wise trend chart plotted. From the chart, we can see that machine-3 is contributing to high defects/rejection as compare to machine-1. Therefore, the main focus area/source is a machine no. 3 for necessary measures to reduce process variation and rejection level.

These seven tools, when used effectively, empower businesses to:

- Identify and eliminate the root causes of quality issues.

- Improve process efficiency and reduce waste.

- Make data-driven decisions for continuous improvement.

- Ensure consistent product or service quality.

By mastering these tools, quality control professionals become champions for excellence, ensuring a company’s commitment to providing its customers with the best possible experience.

Frequently Asked Questions

What is Quality Control?

Quality control is the process of safeguarding that products and services meet predetermined standards. It encompasses everything from inspecting raw materials to testing finished goods, aiming to identify and eliminate defects before they reach the customer.

Why is Quality Control Important?

Enhanced Customer Satisfaction : Consistent quality builds trust and keeps customers loyal, a key factor for ranking higher in search results.

Boosted Brand Reputation : Delivering quality products strengthens your brand image, a positive signal for search engines.

Reduced Costs: Identifying problems early avoids costly rework and recalls, improving your bottom line.

Streamlined Processes: QC data helps pinpoint areas for improvement in production, leading to efficiency gains.

How Does Quality Control Work?

Inspections: Visual checks to ensure products meet specifications

Testing: Running products through simulated or real-world scenarios

Statistical Process Control (SPC): Using data analysis to identify trends and prevent defects

What is the Future of Quality Control?

Automation: Robots and AI are performing inspections with increased speed and accuracy

Big Data Analytics: Analyzing vast datasets helps predict and prevent quality issues

Cloud-Based QC Systems: Sharing data across the supply chain for real-time quality monitoring